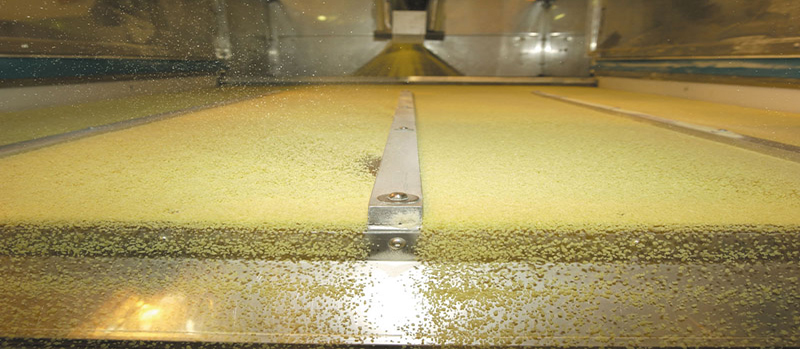

The production of couscous in rolling small grins of semolina, pre-cook them in steam and finally dry them in order to allow longer shelf life. Durum wheat (triticum durum) is used to produce semolina is genetically different than soft wheat from which we make flour that is the basis for making pizza and bread. Our ancestors relied on semolina not flour to make couscous because semolina is more elastic, easier to crush and has multiple nutritive values. Traditionally, couscous the fabrication of couscous was labor- intensive relying generally on a group of woman and many days of work. During this process, grains of semolina are watered and hand rolled to form small balls. These balls are sprinkled with dry semolina to keep them separate. Then they are sieved, sprinkled and rolled again. This process is repeated until the right grain size is finally reached. Couscous is cooked using a utensil made of two parts one of top of the other. The bottom one has boiling water and the top part holds the couscous grains. As the water boils the steam moves upward to the top part. The latter has multiple small holes to allow the steam to cook the couscous in order to get perfectly light and tender grain. This cooking cycle is repeated two to three times. Couscous is now produced at a large scale using industrial machinery. - In order to get semolina, durum wheat is first milled to pure and perfectly calibrated semolina grains. - First, semolina is mixed by progressively adding water in the kneading process. The water temperature should be at 40 degrees and the process lasts 10 to 15 minutes. - The mix of semolina and water falls into a machine called the roller where balls are shaped. Then, a vibrating plate spread the bolls evenly. The ones with right size will go to a machine called the cooker. - Couscous is steamed at 110°C during 11 minutes. - Couscous is dried using a rotater. This critical step is carefully done with specific temperature and moisture settings. - Couscous is then cooled using room temperature. - Then, couscous is transferred via compressed air to a sieve that calibrates grains. - Grains that do not have the right size go through a machine that breaks it into smaller pieces and puts it through the calibrator again. - Finally, couscous is packed either in bulk 5 or 25 Kg or in single packs 500g, 1 Kg.